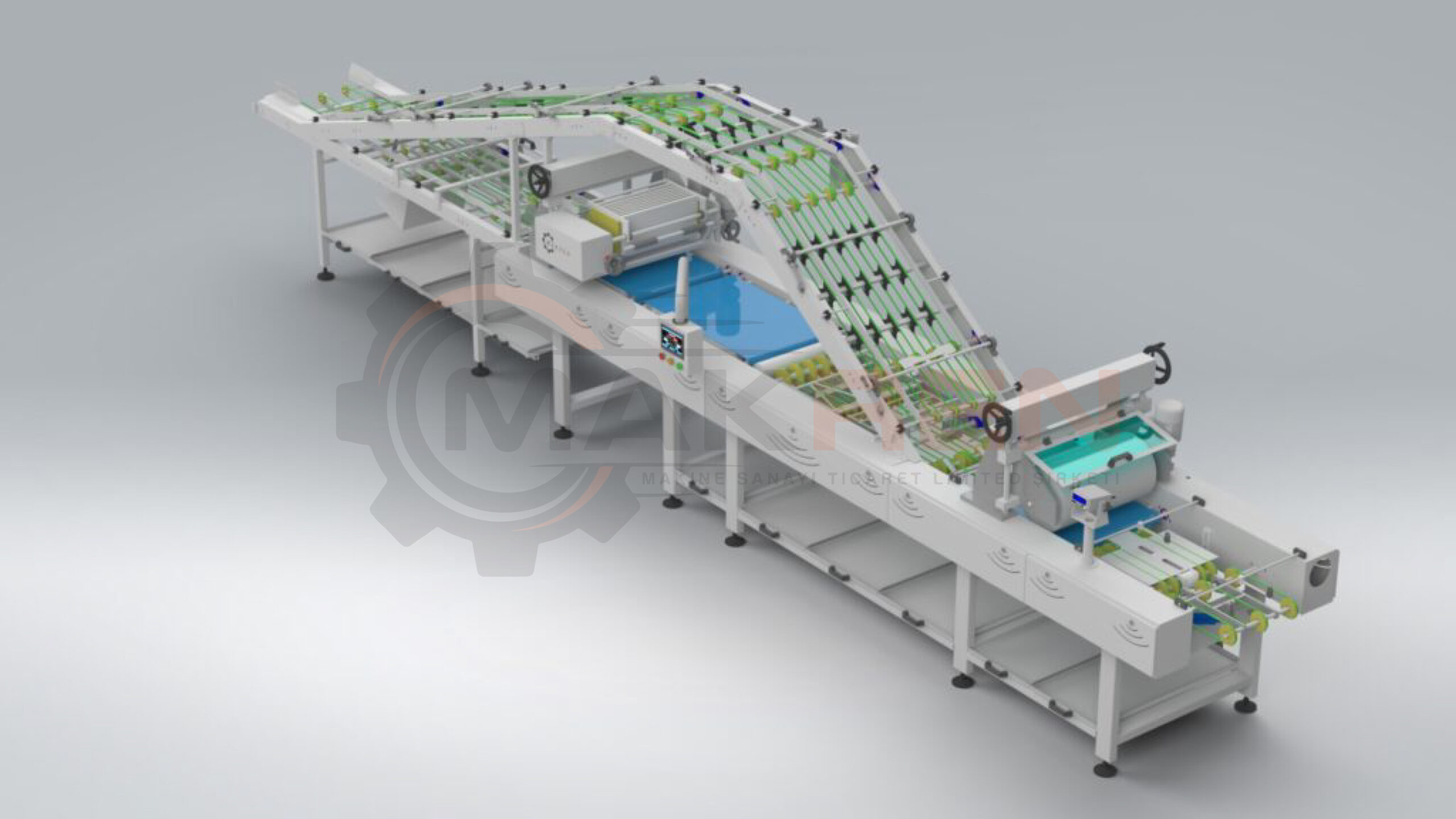

Liquid or air cream is applied on the wafer sheets coming from the sheet cooling to form blocks.

The block is formed by applying 1 layer of cream between 2 leaves. A total of 11 layers are obtained by applying 5 layers of cream between maximum 6 leaves. The block is made with the help of a pneumatic system. The cream can be applied in one or two colors. The cream, which comes over a rotating drum, is poured onto the wafer sheet coming over the belt with the help of scraper blades, and the cream made of stainless steel is poured into the circulation car in order to ensure recycling of the excess cream remaining on the belt, and transfers it back to the cream chamber with the help of the pump. By ironing, the cream is spread between the wafers.

Optionally, there is a block weighing unit after the cylinder. The desired weight can be adjusted and easily followed on the screen. Optionally, hazelnut pouring group is used additionally.

WAFER DIMENSIONS

Runners and bands can be adjusted in accordance with wafer sheets between 290 X 470 – 350 X 500.

CREAM APPLICATION SINGLE HEAD 40 sheets / min Energy consumption 9 kw

CREAM APPLICATION DOUBLE HEAD 40 sheets / min Energy consumption 12 kw

CREAM SLIP DOUBLE HEAD HAZELNUT 40 sheets / min Energy consumption 12 kw

CYLINDER TROLLEY Energy consumption 6 kW

Made entirely of stainless steel. Automatic cream spreading machines are optionally used for making cream fillings on the basis of host or film system. The machine has a driving head, stacking station, printing unit, weight control unit and control panel. Optionally, a second spreading head can be added for cream filling in different colors or flavors. It is suitable for applying minimum 2 and maximum 5 layers of cream. The coefficients of the plates are adjusted automatically.